Features

- Outstanding mixing and heat exchange: patented HEART design

- Low internal volume

- High residence time

- Highly flexible

- Seamless scale-up with other Advanced-Flow™ Reactors products

- High chemical durability

Technical Specifications

| Flow Rate |

Temperature |

Pressure |

Materials |

Fluidic Module |

Options |

| 2 to 10 ml/min – |

60°C to 200°C |

Up to 18 barg |

Glass PFA Perfluoroelastomer |

0.45 ml internal volume |

FDA, cGMp compliance |

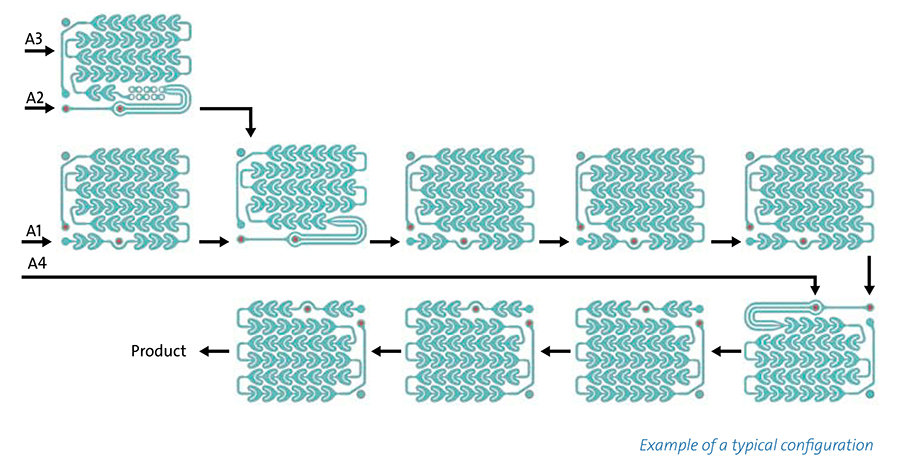

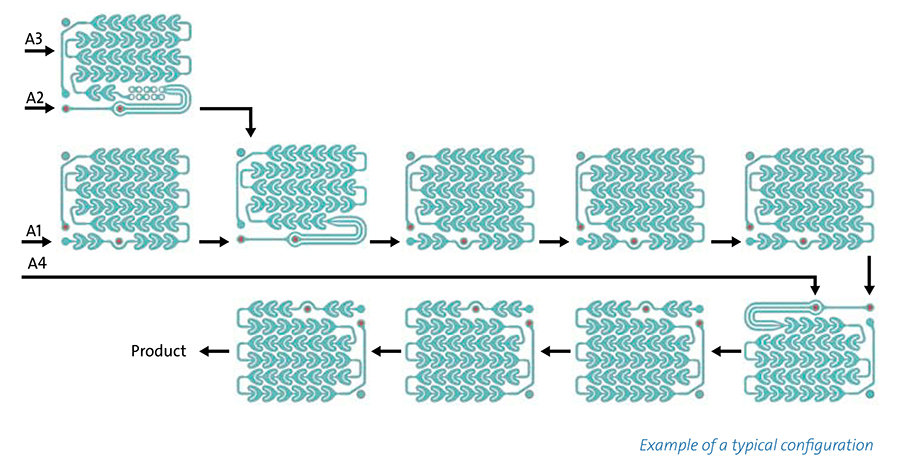

Reactor configuration

Reactor is multipurpose and configuration can be customized. Injection points may be added anywhere on the reactor.

Features

- Outstanding mixing and heat exchange: patented HEART design

- Small internal volume

- High residence time

- Highly flexible and multipurpose

- High chemical durability (suitable for high pH compounds and hydrofluoric acid)

- Hybrid glass / SiC solution

- Seamless scale-up with other Advanced-Flow™ Reactors products

Technical Specifications

| Flow Rate |

Temperature |

Pressure |

Materials |

Fluidic Module |

Options |

| 30 to 200 ml/min |

-60°C to 200°C |

up to 18 barg |

Silicon Carbide Pfa Perfluoroelastomer |

10 ml internal volume |

ATEX Certification; FDA, cGMp Compliance |

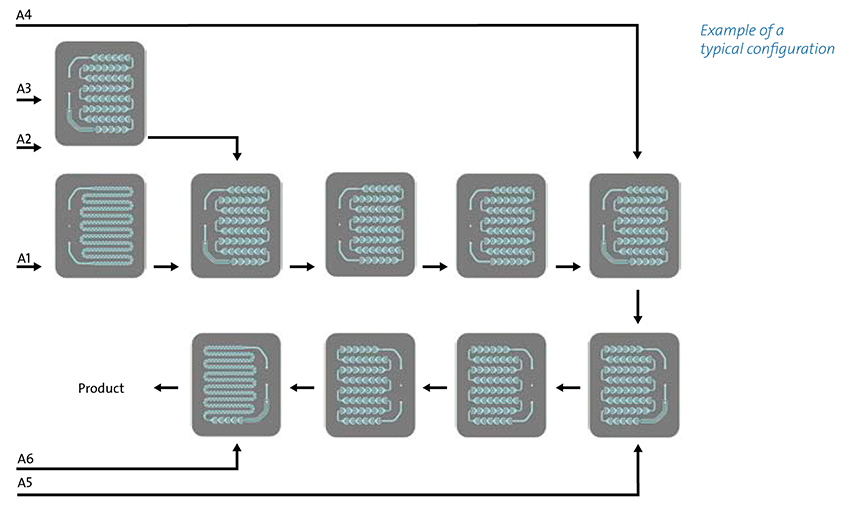

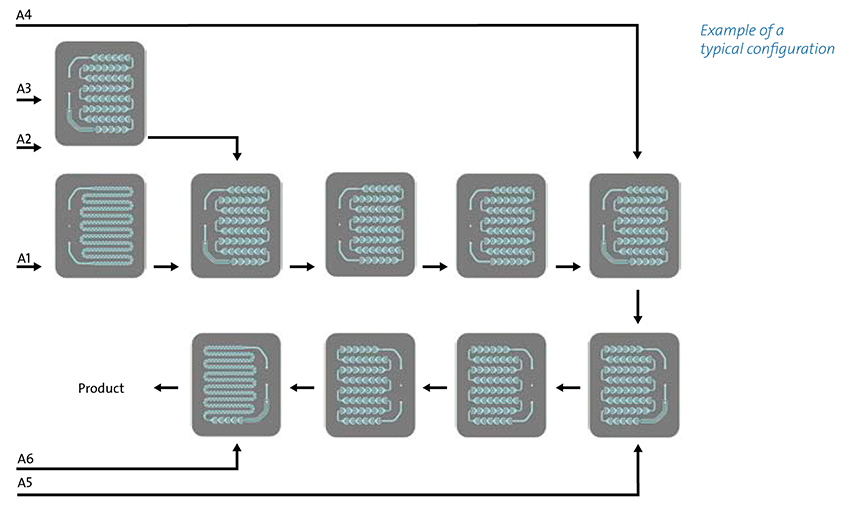

Reactor configuration

Reactor is multipurpose and configuration can be customized. Injection points may be added anywhere on the reactor.

Features

- Outstanding mixing and heat exchange: patented HEART design

- Small internal volume

- High residence time

- Highly flexible and multipurpose

- High chemical durability

- Transparent and compatible with a light module for photochemistry

- Hybrid glass / SiC solution

- Seamless scale-up with other Advanced-Flow™ Reactors products

Technical Specifications

| Flow Rate |

Temperature |

Pressure |

Materials |

Fluidic Module |

Options |

| 30 to 200 ml/min |

-60°C to 200°C |

up to 18 barg |

Glass Pfa Perfluoroelastomer |

9 Ml Internal Volumee |

Fda, Cgmp Compliance |

Reactor configuration

Reactor is multipurpose and configuration can be customized. Injection points may be added anywhere on the reactor.