| DESCRIPTION |

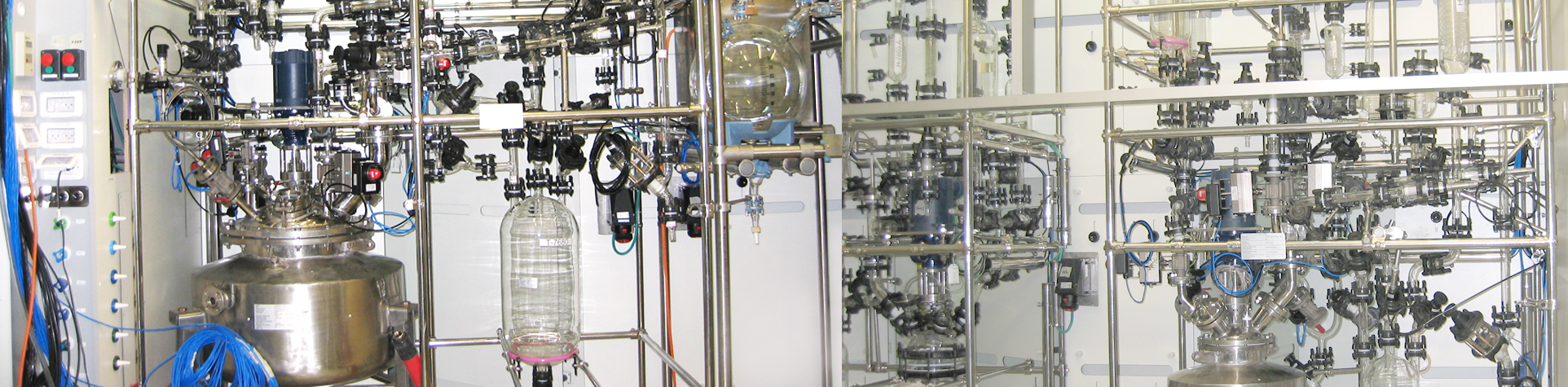

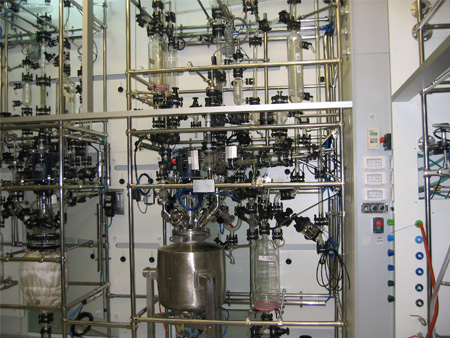

JE-KL-10 |

JE-KL-20 |

JE-KL-30 |

JE-KL-50 |

JE-KL-100 |

JE-KL-200 |

REMARKS / DETAILED DESCRIPTION |

| GLASS MAIN PARTS |

| Glass Cylindrical Reactor |

10L |

20L |

30L |

50L |

100L |

200L |

Option available for Jacketed and Triple Wall (vacuum jacketed) available only upto 100L reactor. L/D ratio of the reactor to be maintained. |

| Top dish |

N1: DN40 (center nozzle)

N2: DN25 (side nozzle)

N3: DN25 (side nozzle)

N4: DN50 (front nozzle)

N5: DN50 (side nozzle)

N6: DN15 (side nozzle)

|

N1: DN50 (center nozzle)

N2: DN25 (side nozzle)

N3: DN40 (side nozzle)

N4: DN80 (front nozzle)

N5: DN80 (side nozzle)

N6: DN25 (side nozzle)

|

N1: DN50 (center nozzle)

N2: DN25 (side nozzle)

N3: DN40 (side nozzle)

N4: DN100 (front nozzle)

N5: DN100 (side nozzle)

N6: DN25 (side nozzle)

|

Option for SS-PFA lined top dish also available. Nozzle schedule can be modified based on the customer’s requirements. |

| SS-PTFE Lined Agitator |

1 |

1 |

1 |

1 |

1 |

1 |

Option available for Anchor, PBT, CBT impeller in single as well as dual stage. Proper L/D ratio shall be maintained. |

| Drive assembly for agitator |

0.25 HP |

0.25 HP |

0.5 HP |

0.5 HP |

1 HP |

1 HP |

Flameproof motor (option available for ATEX certified), gearbox, single mechanical. |

| Glass Feed Vessel |

2L |

5L |

10L |

10L |

20L |

20L |

Options available in cylindrical as well as spherical vessel, also option available for twin vessels.Vessels to be graduated and calibrated. |

| Glass Receiver Vessel |

5L |

5L |

10L |

10L |

20L |

20L |

Options available in cylindrical as well as spherical vessel, also option available for twin vessels as well as single vessel. Vessels to be graduated and calibrated. |

| Glass Vapour Line |

DN40 |

DN50 |

DN80 |

DN80 |

DN100 |

DN150 |

Option available for packing inside the column – structured (eg. Ceramic) or unstructed (eg. Glass Raschig rings) packing. |

| Glass Primary Condenser |

DN80-C; 0.3 sq.m |

DN80-C; 0.3 sq.m |

DN100-C; 0.5 sq.m |

DN150-C; 1 sq.m |

DN150-C; 3 sq.m |

DN225-C; 6 sq.m |

S – Shell & Tube Type

C – Coil Type

(Options available for shell & tube type as primary condenser from 50L onwards) |

| Glass Secondary Condenser |

DN80-C; 0.3 sq.m |

DN80-C; 0.3 sq.m |

DN80-C; 0.3 sq.m |

DN80-C; 0.3 sq.m |

DN100-C; 0.5 sq.m |

DN100-C; 0.5 sq.m |

| Glass Phase Separator |

1L |

2L |

2L |

2L |

2L |

2L |

Dean & stark type phase separator with provision of refluxing / collecting either heavy or light phase as per the demand of the process. Option for horizontal phase separator also available. |

| Glass Vacuum Manifold |

DN50 |

DN50 |

DN50 |

DN80 |

DN80 |

DN80 |

5 Nozzles, drain and vent |

| Glass Ice Trap |

DN80 |

DN80 |

DN80 |

DN100 |

DN100 |

DN100 |

For trapping the escaped vapor and preventing it from fouling the vacuum pump. Ice trap to be filled with either liquid nitrogen or dry ice. |

| Glass Internal Process Pipelines |

DN15 / DN25 |

DN15 / DN25 |

DN15 / DN25 |

DN40 / DN25 |

DN40 / DN25 |

DN40 / DN25 |

|

| Glass Main Vacuum Line |

DN25 |

DN25 |

DN25 |

DN40 |

DN40 |

DN40 |

|

| Glass Vacuum Balance Line to Receivers / Feed Vessels |

DN15 |

DN15 |

DN15 |

DN25 |

DN25 |

DN25 |

|

| Hardware – Plastic flanges, Inserts , SS Nuts, bolts, washers and springs |

SET |

SET |

SET |

SET |

SET |

SET |

Plastic flanges used as per DIN standard. Option available for SS-304 / SS-316 flanges too. |

| Structure – Main Frame – SS304 |

1″ SCH40 pipe |

1″ SCH40 pipe |

1″ SCH40 pipe |

1.25″ SCH40 pipe |

1.25″ SCH40 pipe |

1.25″ SCH40 pipe |

Option available for reactor vessel lifting and lowering with limit switches. |

| SAFETY FEATURES |

| Rupture Disc |

DN40 / DN50 |

DN40 / DN50 |

DN40 / DN50 |

DN40 / DN50 |

DN40 / DN50 |

DN40 / DN50 |

Suitable to withstand vacuum and burst pressure rating of 0.6 bar @ 100 DegC. |

| AUTOMATION AND INSTRUMENTATION |

| Temperature Sensors |

4 |

4 |

4 |

4 |

4 |

4 |

Reactor temp, Vapour temp, Vent temp and Product temp. Sensor of reputed make (FLP enclosure) Duplex 3 wire Class A PT100 sensors to be used. |

| Pressure Transmitter / Dial Gauge |

1 |

1 |

1 |

1 |

1 |

1 |

Please choose between pressure transmitter and dial gauge as per your requirement. |

| Agitator RPM controller (VFD) |

1 |

1 |

1 |

1 |

1 |

1 |

Reputed make VFD to be used. |

| Operation & Indication Panel |

1 |

1 |

1 |

1 |

1 |

1 |

Option available for:

1) Ex d enclosure (Ex II 2GD Ex DB)

2) PLC with ATEX / NON-ATEX approved HMI |

| HMI with PLC panel (Optional) |

Touchscreen HMI can be provided inside flameproof enclosure along with PLC panel |

Option available for:

1) Ex d enclosure (Ex II 2GD Ex DB)

2) PLC to be placed in safe area. |

| SCADA Automation Solution (Optional) |

PC workstation for controlling, storing and reviewing of process parameters of the assembly |

CFR21 PART 11 compliant SCADA automation solutions, pre-defined recipe formulation as per process requirements also available. |

| ADDITIONAL ACCESSORIES / INFORMATION |

| Reactor lifting and lowering system |

Stainless steel lifting and lowering system for reactor vertical movement (up & down) |

Used for cleaning and ease of agitator interchangeability. |

| Heating & Cooling system |

Different models of several temperature ranges and power (kW) are available |

Do visit our product page (temperature control unit) for selection of the right model. |

| Documentation (Optional) |

SET |

SET |

SET |

SET |

SET |

SET |

Complete set of documentations and certifications to be provided along with the system. |

| Approximate Foot Print |

L: 1900 mm

W: 1200 mm

H: 3100 mm

|

L: 2000 mm

W: 1000 mm

H: 3300 mm |

L: 2000 mm

W: 1200 mm

H: 3300 mm |

L: 2150 mm

W: 1300 mm

H: 3300 mm |

L: 2400 mm

W: 1500 mm

H: 3800 mm |

L: 2650 mm

W: 1500 mm

H: 4200 mm |

Based on the client’s requirements, we can modify the system and try to accommodate in the available area. These footprint area is approximate, do confirm with us

once. |